Military material factory

Military Materials factory was established in 2009 on the basis of the Protective Materials Production Workshop under the Sub-Institute of Tropical Durability. The main function of the Military Materials factory is to receive research products from research laboratories of the Institute of Tropical Durability, coordinate with other Laboratories to improve product quality, develop standards and deploy production to supply for units in need.

CAPACITY

- Producing all kinds of protective materials such as: preservative oils, preservative greases, cable greases, non-drying flexible mastic, oil resistant mastic, tire paint AO-1, bituminous paint BT-97, anti-shock liquid Steol-M, volatile corrosion inhibitor paper, paint remover, rust remover, phosphating solution.

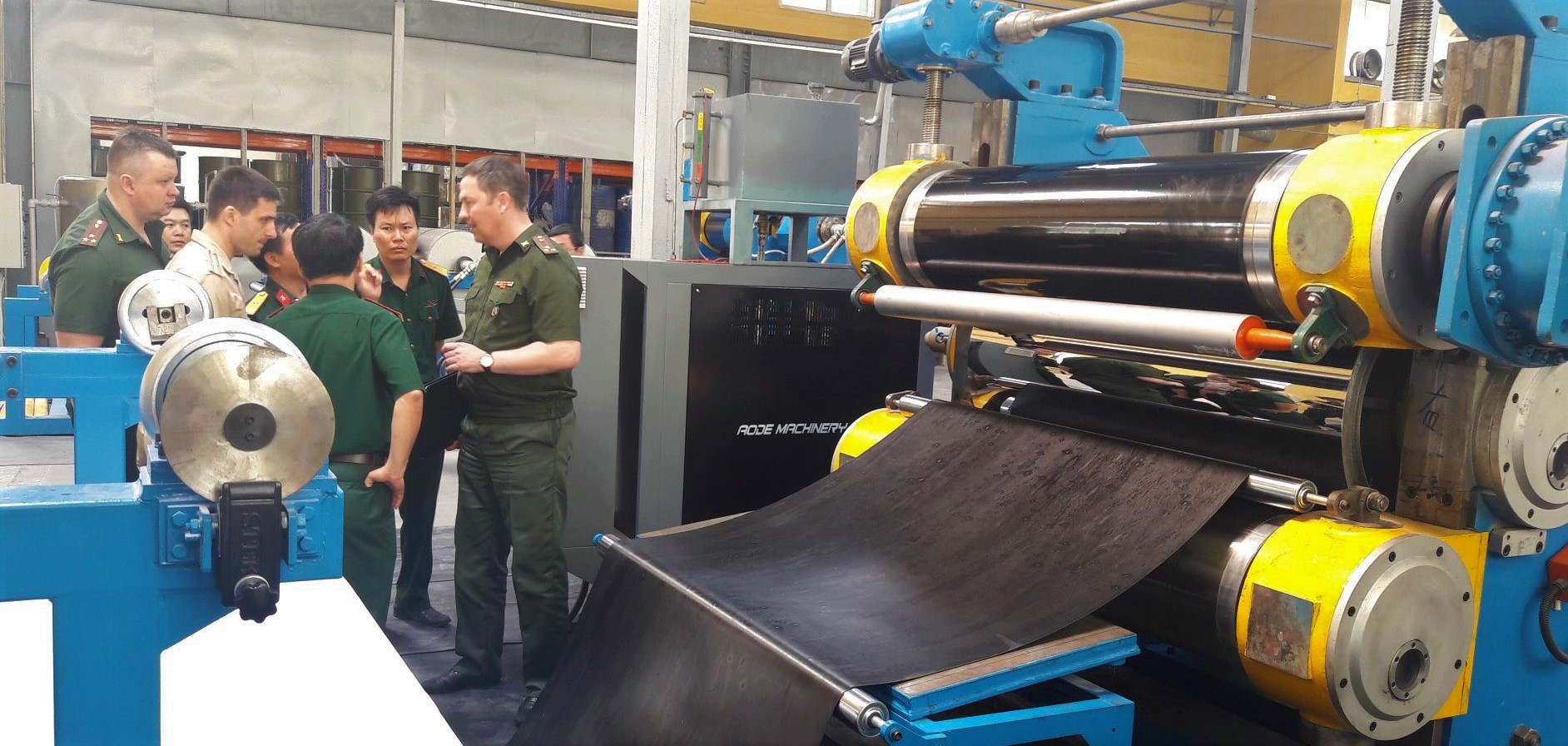

- Producing technical rubber products such as: anti-static rubber, conductive rubber, oil resistant rubber; weather resistant rubber, heat resistant rubber, wear-resistant rubber, gasket,...

FACILITIES AND EQUIPMENT

- The area of office, laboratory, factory is nearly 2000 m2. Preservative oil and grease production and processing lines with an automatic filling system with a total capacity of 2000 tons/year. Technical rubber production equipment line;

- KCS Laboratory with full equipment to check and evaluate the quality of oil and grease products; Analytical capacity has been recognized by the Bureau of Accreditation (BOA) in accordance with ISO/IEC 17025:2017.

RESULTS

Annually, Military Materials Enterprise produces and supplies to the market over 1,500 tons of products, typically: preservative oils (over 150 tons/year), preservative oils (20 tons/year), preservative greases (15 tons/year), AO-1 tire paint (12 tons/year), MT-97 non-drying flexible mastic (15 tons/year), Steol-M hydraulic fluid (10 tons/year), complex wax (300 tons/year), fireproof paint....